Description

ATEX Explosion Proof Certification

Wet/Dry Pneumatic Cleaner SP100(100Liter)

IMPA CODE: 590709

Country of Origin: South Korea

Model: SP100 (100Liter)

Video

MROVIA

(Explosion Proof Cleaner Brand CKTECH)

Contact

Phone: +82-51-903-1302

Mobile phone: +82-10-9311-1302

e-mail : sales@mrovia.com

This product is also can buy through your partner or our partner.

Our partner companies

1. Pungseng

Website: http://pungseng.co.kr/en/

2. Berg&Larsen

Website: https://berg-larsen.com/

3. Expertline ventures corporation

Website: https://expertline.com.ph/

4. JAPAN MARINE GROUP

Website: https://jmsgroup.jp/

Recognized Performance and Durability

Acknowledged for its excellent performance and durability through numerous supply records.

It's 50% cost savings

Applying IMPA CODE

SP100(100Liter) IMPA CODE: 590709

SP20(20Liter) IMPA CODE: 590704

SP40(40Liter) IMPA CODE: 590701

SP75(75Liter) IMPA CODE: 590709

Key Benefits of MROVIA

(CKTECH: Cleaner Brand of MROVIA)

Explosion-Proof Vacuum Cleaners

- Cost-Effective Product: Provides high cost-effectiveness at a price less than 50% existing maker products.

- ATEX Certification: Certified by ATEX, an international explosion-proof certification, confirming its performance and safety.

- Fast Delivery: Capable of faster delivery within 5-7 days compared to existing products.

- No minor breakdowns & No additional maintenance costs : Operates with pneumatics, resulting in no minor breakdowns and no additional maintenance costs.

- Extended Warranty: Offers a warranty of 3 years, which is three times the warranty period compared to other companies (excluding customer negligence).

- Long-Lasting Durability: Guarantees high durability with a minimum use period of 10 years, compared to the replacement cycle of 6 months to 1 year for electric vacuum cleaners.

- Suitable for High-Risk Areas: Can be used in more dangerous places than conventional electric explosion-proof vacuum cleaners, including gas zones (Zone 1, Zone 2) and dust zones (Zone 21, Zone 22).

ATEX Explosion Proof Certification

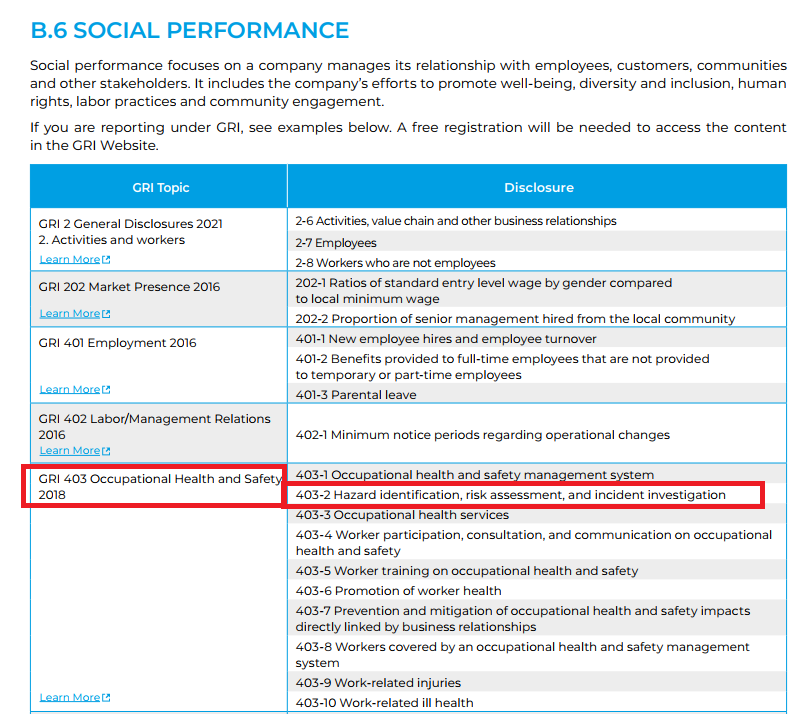

ESG and Other Effect

ESG ratings rise

Preparation for the Serious Disaster Punishment Act

Risk assessment score rise

1. Control risk factors

2. Block risk factors

3. Improve risk factors

◈ ESG ratings rise

Recently, it is essential for exports and sustainable growth.

It is an equipment that meets the safety of ESG,

S(Social) and can be used to increase ESG ratings.

◈ Preparation of the Serious Disaster Punishment Act

Explosive areas, clean rooms, places with

explosive substances, etc

It is an equipment with explosion-proof technology

that can be used.

◈ Risk assessment score rise

If you use it, instead of spending a few tens of thousands ,

you can spend a few thousand dollars

It helps with Risk assessment score at a low cost!

Equipment for increasing the ESG Social sector evaluation grade, risk assessment evaluation score improving hazardous/dangerous environments.

It can be applied to safety, shared growth, and customer relationships in S (SOCIAL) during ESG evaluation.

We have summarized the applicable items of our product through the ESG factor table.

ESG(S: SOCIAL) Detailed Item Table

Reference

- SAMSUNG SDI (Secondary battery material powder removal)

- REPUBLIC OF KOREA Nuclear Power Plant(Cleaning of pollutants in electrical facilities)

- REPUBLIC OF KOREA Thermal Power Plant(Cleaning of pollutants in electrical facilities)

- REPUBLIC OF KOREA Air Force (Remove contaminants in the maintenance/Repair Place)

- Gyeonggi-do Economics and Science Promotion Agency 3D Printing Center(3D printer powder cleaning)

- Korea Carbon Convergence Research Institute(3D printer powder cleaning)

- SAMSUNG ELECTRONIC(Remove pollutants from explosion-protected areas)/ Stainless type)

- LG CHEMISTRY(Removes silica gel, desiccant)

- LG Electronics (clean room cleaning)

- KUMHO P&B CHEMICALS(Chemical substance removal)

- CJ CheilJedang (Wet-dry pollutant removal)

- Songwon Industrial(Removal of pollutants in explosion-proof areas)

- Poongsan Corporation(Ammunition/metal alloy manufacturing enterprise)

- AkzoNobel Industrial Coating (World's No. 1 paint company:Removes paint powder in explosion-proof areas)

- PPG(World's No. 2 paint company:Removes paint powder in explosion-proof areas)

- KOREAN AIR(Removal of oil remaining in the aircraft during aircraft maintenance)

- LG Hausys(Removal of urea granules and other chemical products)

- Hanwha Ocean (Yard and Ship Block/Ship Wet Dry Pollutant Cleaning)

- Samsung Heavy Industries(Yard and Ship Block/Ship Wet Dry Pollutant Cleaning)

- Hyundai Heavy Industries(Yard and Ship Block/Ship Wet Dry Pollutant Cleaning)

- NC Chem Corp(Industrial film maker/Oil and chemical liquid removal)

- MAERSK LINE (Cleaning engine room/deck/storage and other places)

- HMM (Cleaning engine room/deck/storage and other places)

- Hyundai Steel(Remove steel Powder)

- Mercedes-Benz (Mercedes Auto Repair Center)

- MAXROTEC(Robots, automobile parts, 3D printers, engine parts manufacturers/ 3D printing powder and metal powder removal)

- SAONGWON (Remove the frying powder from the oil in the fryer)

- ILSHINTECH (Mobile phone parts manufacturer)

- KOMAN (Hydraulic hose/parts)

- DL E&C Co.,Ltd. (removal of fine powder chemicals

- NOBELIS(World's No. 1 aluminum company: aluminum powder removal)

- Anheuser-Busch InBev SA/NV South Korea Beer Factory(Cleaning to beer raw materials with a risk of ignition)

It has been officially certified for stability and performance by ATEX explosion proof, an international explosion proof certification.

It can prevent industrial accidents by preventing safety accidents on site.

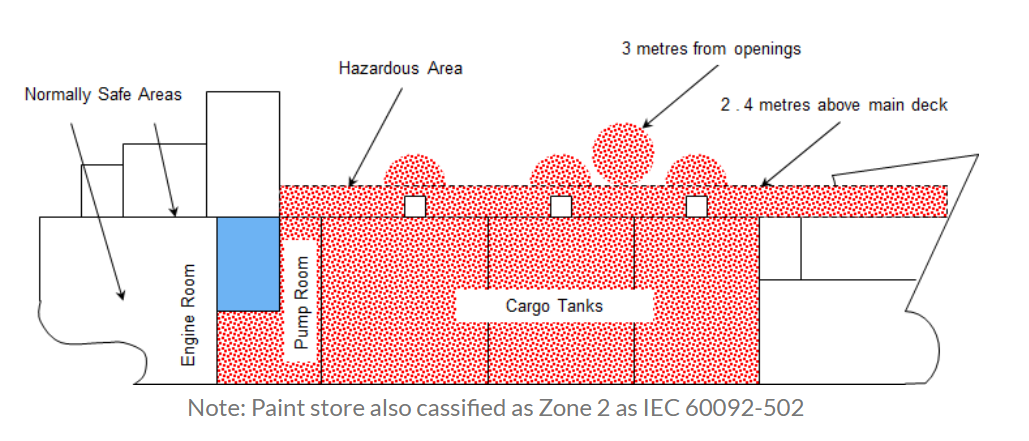

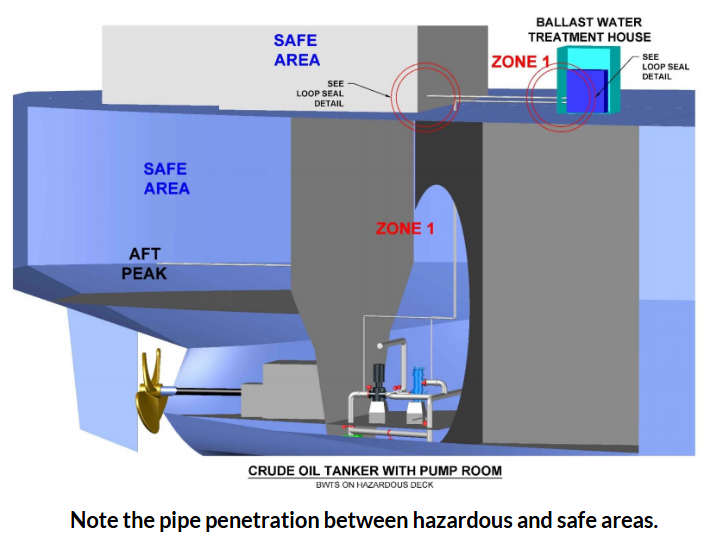

Area of Use(ZONE)

A normal electric explosion proof vacuum cleaner is Zone 2 in a gas location,

Available in Zone 22 in dusty locations.

However, MROVIA 's explosion proof vacuum cleaner is a high-level risk area

Available in Gas Place Zone 1, Zone 2 Dust Place Zone 21, Zone 22.

Specification

ATEX explosion proof certification explosion proof

Wet/Dry Pneumatic cleaner / air cleaner

SP series SP 20, SP 40, SP 75, SP100

| Specifications of the product |

SP20

|

SP40

|

SP75

|

SP100

|

| Size (Width x Length x Height) / mm |

440X440X590

|

460X510X830

|

600X625X970

|

660X700X1150

|

| Tank capacity(Liter) |

20Liter

|

40Liter

|

70Liter

|

100Liter

|

|

Air Consumption(Liter /min) |

600

|

600

|

900

|

1200

|

| Air Inhalation (L/min) |

6000

|

6000

|

9000

|

12000

|

| Weight(Kg) |

8

|

15

|

50

|

75

|

| Material |

High Strength P.P / Stainless

|

|||

| Option |

Antistatic hoses / conductive hoses (For inhalation of explosive/powder substances)

|

|||

Equipped with HEPA filter Steinless Type

SAS40

| Specifications of the product |

SAS40 (40Liter) |

|

Size (Width x Length x Height) / mm |

370X470X720 |

|

Air Inhalation (L/min) |

6000 |

|

Air Consumption(Liter /min) |

600 |

|

Weight(Kg) |

17 |

|

Material |

Stainless steel (head/body)

Equipped with a HEPA filter(Captures over 99.97% of particles 0.3μm in size) |

|

Key Features

|

Semiconductor industry / Fine chemical industry / Flour industry, etc. Fine powder removal possible

|

|

Explosion-proof additional options

|

Anti-static hose(for suctioning explosive materials) |

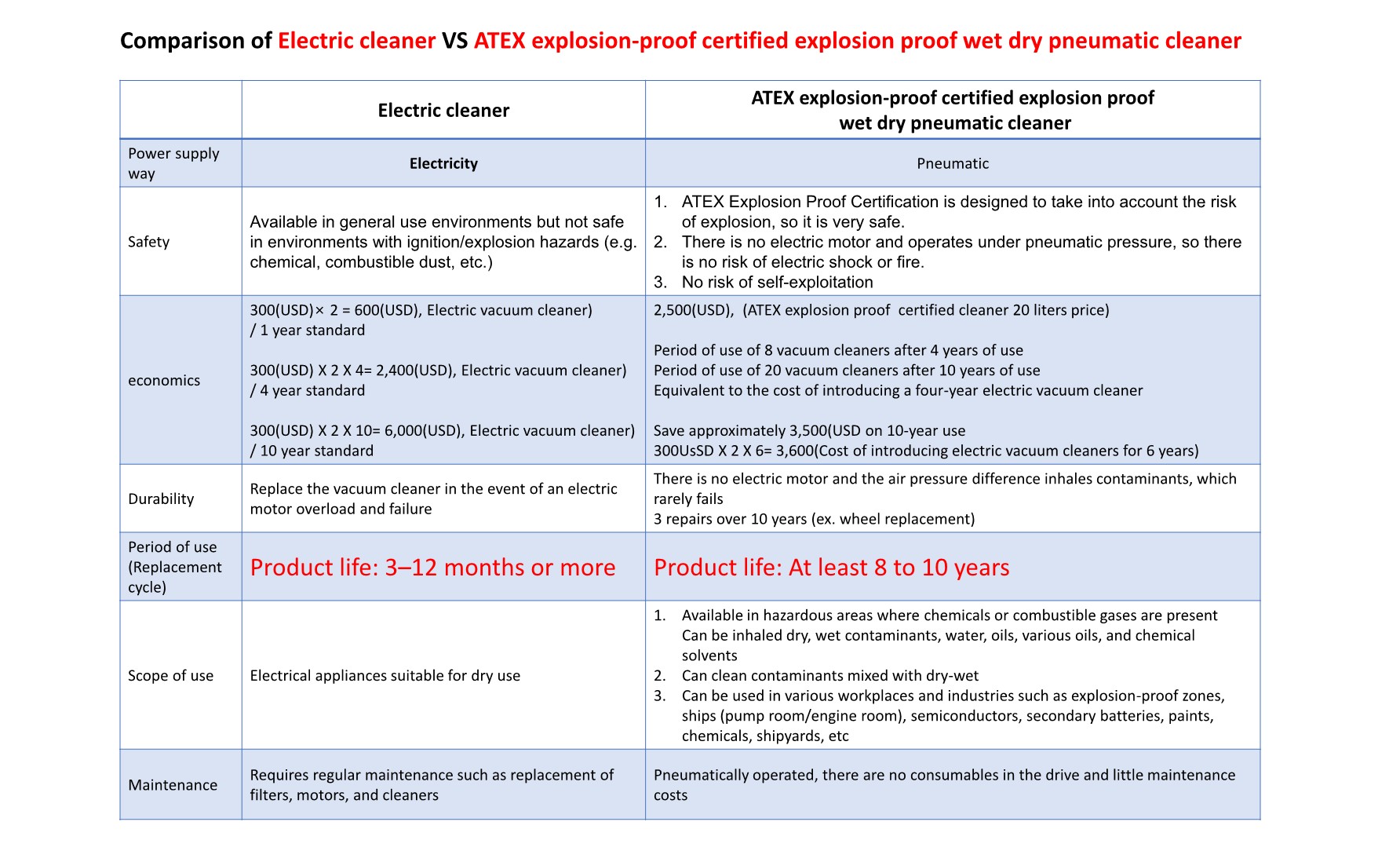

Comparison Table Comparing the operational safety and effectiveness.

Electric Cleaner VS

ATEX Explosion-proof certified Wet&Dry Pneumatic Cleaner

Main Advantage

- Prevents electric shock/fire, No risk of self Fire/Electric shock/Explosion.

- Water / Oil / Dust / Residue at one equipment Suction, removal is convenient.

- Excellent Durability makes it possible to significantly reduce management costs.

Major Technology

- Operated with compressed air without an electric motor

- Such as stainless steel/plastic/aluminum Made of materials that do not self-ignite/emission/explosion

- Backflow prevention function

- There are no rotator parts that cause sparks.

※ It absorbs contaminants with a technology that amplifies the degree of vacuum.

Inhalation substance

It can remove various pollutants with one vacuum cleaner such as water, oil, dust, screws, nails.

Place of use

- Used in explosion-proof areas and other places with a lot of water/oil.

- Water/greasy places such as explosion proof zones, clean rooms, pump rooms, ships (pump rooms, engine rooms), storage, machine rooms, maintenance windows, etc

- Available ships(LNG, tankers, chemicals, containers, offshore plants, cruises, warships, etc)

- Pump rooms in Onshore, Offshore, Ship

- Work Shop/machine rooms in Onshore, Offshore, Ship

Onshore, Offshore and ship cleaning require special attention for safety and efficiency.

Notably, pump rooms are connected to cargo tanks, potentially creating hazardous environments,thus requiring explosion-proof equipment and safety measures.

Anchor chain storage rooms and oil storage facilities are cleaned using

high-pressure washers and explosion-proof cleaners.

Industries and Place to use

1. Explosion-proof areas, Hazardous area and clean rooms

(Semiconductor/Chemical/Paint/Oil refining/Electronics/Electricity/Other)

Explosion-proof areas & Hazardous area

Explosion-proof areas & Hazardous area

Clean rooms

2. Explosion-proof areas & Hazardous area

Onshore/Oil refinery/Chemical plant plant/Steel mill/

Paint factory/Paper mill/Other factories

Onshore /Oil refinery/Chemical plant plant

Steel mill

Paint factory Paper mill

Paper mill

3. Offshore(FPSO:Floating Production, Storage, and Offloading)

/Drillships/Jack-up drilling rigs/Fixed Platforms/Semi-submersible Platforms

/Tension Leg Platforms (TLPs)/Spar Platforms

Ship(BULK/CONTAINER/LNG,/LPG/CRUISER/Warship etc.)

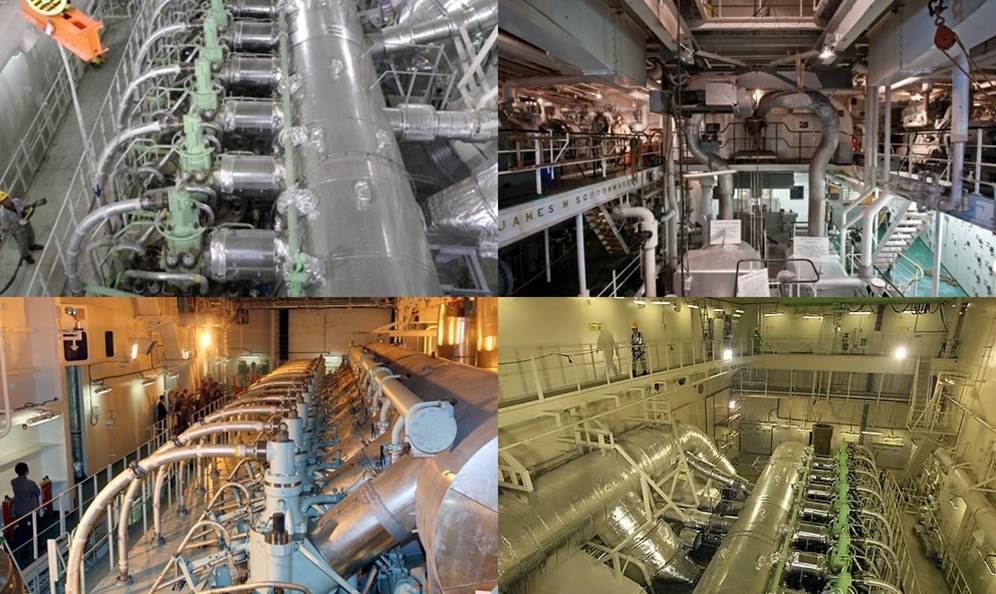

Place of use

Sewage tank/Lube oil tank/ Water Tank/Pump Room

/Discharge pipe broken/Condenser area/Work Shop

/Deck/Engine Room

Place of use Video

Sewage tank cleaning

Lube oil tank cleaning

Lube oil tank cleaning

Water Tank Cleaning

Condenser area

Get flood in ER.

Discharge pipe broken

Tank cleaningWork Shop

In a ship workshop, explosion-proof vacuum cleaners are used to safely clean hazardous environments. These cleaners minimize the risk of electrical shock and fire, especially in areas with flammable materials. They typically operate using compressed air and feature anti-static grounding to prevent sparks.

Work Shop Cleaning

Cleaning of marine plants and ships involves various locations and situations. Notably, pump rooms are connected to cargo tanks, potentially creating hazardous environments, thus requiring explosion-proof equipment and safety measures.

In a ship workshop, explosion-proof vacuum cleaners are used to safely clean hazardous environments. These cleaners minimize the risk of electrical shock and fire, especially in areas with flammable materials. They typically operate using compressed air and feature anti-static grounding to prevent sparks.

Key Features of Explosion-Proof Vacuum Cleaners:

- Safety Assurance: Prevents electrical shock and fire hazards, ensuring worker and equipment safety.

- Compressed Air Operation: Uses compressed air instead of electricity, eliminating sparks and static electricity.

- Anti-Static Grounding: All components are grounded to prevent static electricity buildup.

- Handling Flammable Materials: Safely cleans flammable dusts and liquids.

These vacuum cleaners are essential tools in maintaining safety and efficiency in Onshore, Offshore and ship workshops.

Pump Room Cleaning

- Use of Explosion-Proof Equipment: Since pump rooms can be classified as explosion zones, equipment with explosion-proof certification must be used.

- Cleaning Procedure: Regular cleaning is essential, especially in areas connected to cargo tanks. Water or cleaning agents are used to remove contaminants.

- Safety Measures: Always wear safety gear and use appropriate ventilation systems during cleaning.

Cleaning of Anchor Chain Storage Rooms and Oil Storage Facilities

- Use of High-Pressure Washers and Cleaning Agents: Anchor chains and interiors are cleaned, and any remaining sludge or oil residue is cleaned with explosion-proof cleaners.

- Main Causes of Gas Generation: Corrosion of metal structures, poor ventilation, and oxygen deficiency can lead to gas generation.

Engine Room

Cleaning after replacing engine and generator parts

Other Areas

- Cargo Tanks and Related Facilities: The interiors of cargo tanks, slop tanks, piping, and equipment for pressure relief systems typically fall under Zone 0.

- Pump Rooms and Areas Around Cargo Tanks: Spaces near cargo tanks, pump rooms, and areas around cargo tank outlets generally fall under Zone 1.

Hazardous are within the SHIP

4. Remove 3D Printer Powder

3D Printer Powder Removal Video

5. Shipyard, repair shipyard, ship block,

ship block factory, ship engine parts factory

Shipyard /ship block

Shipyard

ship engine parts factory

6. Naval Maintenance Depot , Air Force Maintenance Depot ,

Army Consolidated Maintenance Depot , Railway Maintenance Depot ,

Subway Maintenance Depot,

Aircraft Maintenance Depot(Aircraft Oil Tank Residue Cleaning)

Naval Maintenance Depot

Naval Maintenance Depot

Naval Maintenance Depot

7. Thermal Power Station/hydroelectric power plant

/nuclear power /solar power plant /Combined cycle power plant

8. Sewage treatment plant

Sewage treatment plant Video

9. HACCP certification (Pharmaceutical/Food/Fisheries/Fisheries/Other)

HACCP Certified Food Factory HACCP Certified Pharmaceutical Factory

HACCP Certified Pharmaceutical Factory

HACCP Certified Pharmaceutical Factory

HACCP Certified Pharmaceutical Factory Food factory

Food factory Food factory

Food factory Food factory

Food factory Food factory

Food factory Seafood processing plant

Seafood processing plant Livestock processing plant

Livestock processing plant Agricultural processing plant

Agricultural processing plant Agricultural processing plant

Agricultural processing plant 10. Water tank cleaning/facility cleaning

10. Water tank cleaning/facility cleaning

Water tank cleaning

Factory/Facility cleaning

Factory/Facility cleaning

11. Car maintenance center

11. Car maintenance center

12. Storage

Equipment manufacturing and engineering company

(Used as air system components for large-scale equipment/equipment cleaning)

MROVIA

(Explosion Proof Cleaner Brand CKTECH)

Contact

Phone: +82-51-903-1302

Mobile phone: +82-10-9311-1302

e-mail : sales@mrovia.com

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.